TL2005

TALFRI

TL2005

Red Copper Wire/roll

0.60

650F(340℃)

600F(315℃)

Datesheet

| Availability: | |

|---|---|

| Quantity: | |

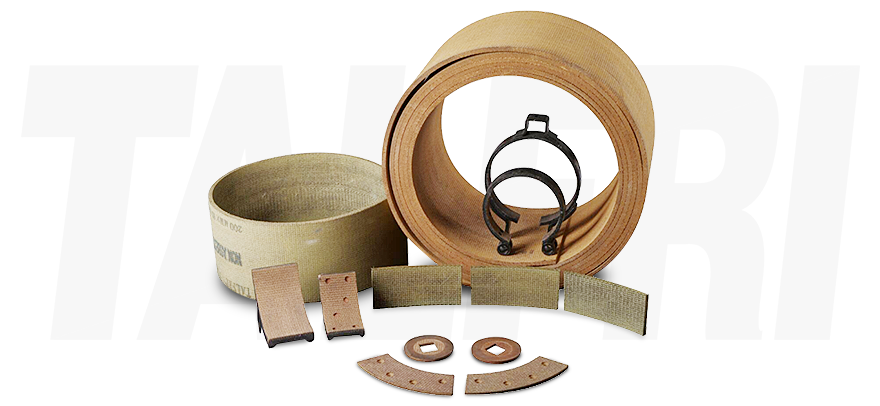

Overview

TL2005 is a semi-rigid Non Asbestos Brake Lining specially designed for super heavy duty applications. The material is densely woven from various synthetic fiber yarns and copper wire and impregnated with special resins. This dense, tough material exhibits exceedingly good resistance to heat and compression under heavy load.

TL2005 has excellent fade and recovery stability, and it is suitable for cast iron and steel working surface.

✅ Ultra-Durable Construction: Woven from yarn, glass fiber, and brass wire, then resin-impregnated and then grinding

✅ High Wear & High Quality Resistance: Withstands extreme mechanical and thermal loads

✅ Customizable Options: Available max width 510mm, thickness 3.2-35mm, length 10-15mtrs one roll specifications

✅ Lead-Free, Asbestos-Free, Environmentally Safe

✅ High coefficient & High density & High temperture for tailored marine winch windlass , Port dredging and industrial clutch/brake configurations

Dimension:

Width: Max 510mm ( 20inches )

Thickness:3.2mm—35mm ( 1/8 – 1.378 inch)

Length:10-15Mtr

Frictional Properties:

Normal 0.60

Hot 0.58

400°F 0.60

Recommended Operating Range:

Max. Pressure, psi 600

Max. Rubbing Speed, ft/min 5000

Max. Intermittent Temperature 650°F (340°C)

Max. Continuous Temperature 600°F (315°C)

TL2005 woven brake lining rolls are widely adopted in:

Industrial brake and clutch systems

Port dredging、channel cleanout

Oil drilling equipment winch

Elevator、Crane、Hoist

Heavy-duty loader、mining machinery、construction machinery

Deck machinery winch、windlass、chain wheel、Cable lifter

With over 25 years of experience, Guiyang Talfri Brakes Co., Ltd. is the first and only Chinese manufacturer of non-asbestos laminated friction materials. Backed by imported technology and a commitment to innovation, we serve global clients in over 75% export markets including the USA, Europe, Korea, and Australia.

ISO 9001:2015 & IATF 16949:2016 certified

DNV & CCS quality type approved

Fully compliant with SAE-J661 & asbestos-free standards

Traceable production with inspection reports, CoC, and performance tests available

Inspect every batch of raw materials follow the technical requirements

On-site inspection during processing

Final inspection

Test performance report for every batch of products

Batch number print on the product for track

24 hours online

Have a professional after-sales team

Size inspection reports and performance test reports keep record available for tracking

Provide feasible suggestions and solutions

Looking for a long-lifespan, non-asbestos, and high-quality woven brake lining and brake pads supplier?

Talfri offers various of non asbestos brake lining 、brake pads、friction blocks and the performance, safety, and reliability meet the global marine and industries demand.

Contact us today to request samples, technical data sheets, or custom solutions tailored to your equipment needs.

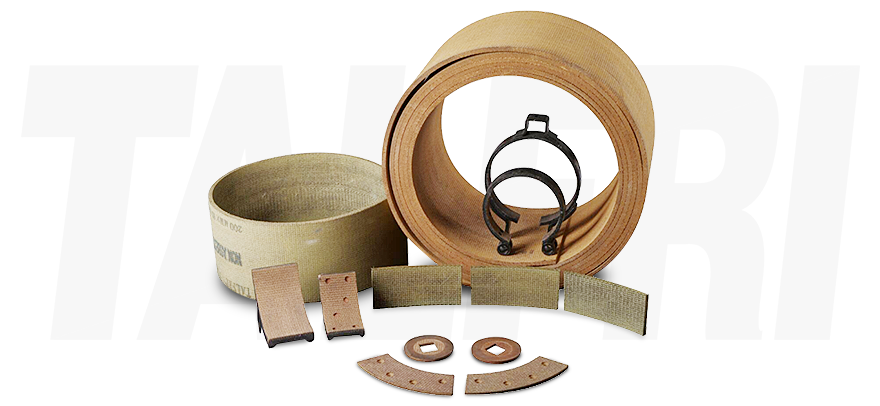

Overview

TL2005 is a semi-rigid Non Asbestos Brake Lining specially designed for super heavy duty applications. The material is densely woven from various synthetic fiber yarns and copper wire and impregnated with special resins. This dense, tough material exhibits exceedingly good resistance to heat and compression under heavy load.

TL2005 has excellent fade and recovery stability, and it is suitable for cast iron and steel working surface.

✅ Ultra-Durable Construction: Woven from yarn, glass fiber, and brass wire, then resin-impregnated and then grinding

✅ High Wear & High Quality Resistance: Withstands extreme mechanical and thermal loads

✅ Customizable Options: Available max width 510mm, thickness 3.2-35mm, length 10-15mtrs one roll specifications

✅ Lead-Free, Asbestos-Free, Environmentally Safe

✅ High coefficient & High density & High temperture for tailored marine winch windlass , Port dredging and industrial clutch/brake configurations

Dimension:

Width: Max 510mm ( 20inches )

Thickness:3.2mm—35mm ( 1/8 – 1.378 inch)

Length:10-15Mtr

Frictional Properties:

Normal 0.60

Hot 0.58

400°F 0.60

Recommended Operating Range:

Max. Pressure, psi 600

Max. Rubbing Speed, ft/min 5000

Max. Intermittent Temperature 650°F (340°C)

Max. Continuous Temperature 600°F (315°C)

TL2005 woven brake lining rolls are widely adopted in:

Industrial brake and clutch systems

Port dredging、channel cleanout

Oil drilling equipment winch

Elevator、Crane、Hoist

Heavy-duty loader、mining machinery、construction machinery

Deck machinery winch、windlass、chain wheel、Cable lifter

With over 25 years of experience, Guiyang Talfri Brakes Co., Ltd. is the first and only Chinese manufacturer of non-asbestos laminated friction materials. Backed by imported technology and a commitment to innovation, we serve global clients in over 75% export markets including the USA, Europe, Korea, and Australia.

ISO 9001:2015 & IATF 16949:2016 certified

DNV & CCS quality type approved

Fully compliant with SAE-J661 & asbestos-free standards

Traceable production with inspection reports, CoC, and performance tests available

Inspect every batch of raw materials follow the technical requirements

On-site inspection during processing

Final inspection

Test performance report for every batch of products

Batch number print on the product for track

24 hours online

Have a professional after-sales team

Size inspection reports and performance test reports keep record available for tracking

Provide feasible suggestions and solutions

Looking for a long-lifespan, non-asbestos, and high-quality woven brake lining and brake pads supplier?

Talfri offers various of non asbestos brake lining 、brake pads、friction blocks and the performance, safety, and reliability meet the global marine and industries demand.

Contact us today to request samples, technical data sheets, or custom solutions tailored to your equipment needs.